The best solution

“We develop, operate, and market the very best solution by far for biomass processing."

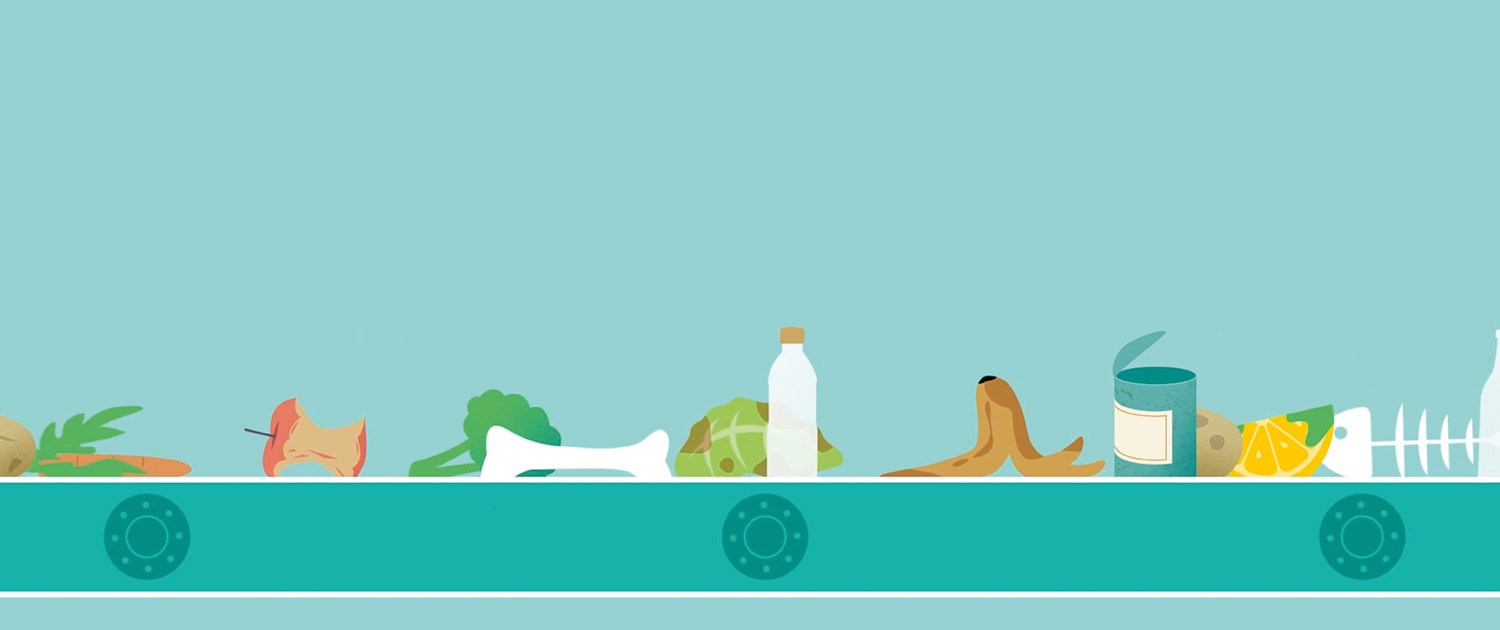

This is how it works.

When we receive waste at Organicum, we separate and sort glass, metal, plastic, cardboard, and other foreign bodies from the organic part of the waste. We convert pure organic waste into high-quality biomass. Wherever possible, metal, plastic, and glass are sent for recycling. This ensures a very high recycling rate on the waste we receive. The biomass is sent on to bioenergy plants for the extraction of green and CO2-neutral biogas, which is the most sustainable way of producing energy.

Watch the film to learn more about our innovative process.

Waste is also about IT.

Our in-house developed software is a significant reason why we can ensure the high quality that characterizes biomass from Organicum Biomass. With the platform, we can tailor the biomass to the individual biogas producer and offer the suppliers of the organic waste full traceability. It relieves internal resources and ensures reporting to relevant authorities, which we believe will become more and more important in the future.

Get in touch and let us know what you need.

We would like to hear about your wishes and are available if you have any questions. Contact us and find out more about the production of sustainable energy based on organic waste.